These instructions are outdated and incomplete, they are retained for reference only

the up to date instructions are here

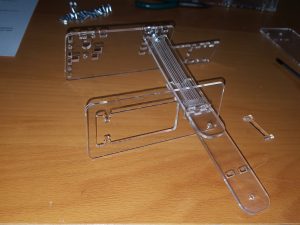

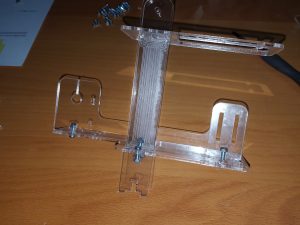

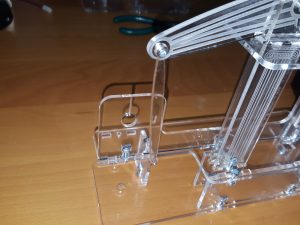

Start with the top base, two pillars and the gallery.

Start with the top base, two pillars and the gallery. Insert one of the columns through the gallery

Insert one of the columns through the gallery Insert the second column through the gallery

Insert the second column through the gallery and secure with the I beam. You may want to secure the I beam in place with a small piece of tape whilst building the rest of the kit.

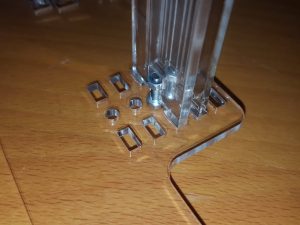

and secure with the I beam. You may want to secure the I beam in place with a small piece of tape whilst building the rest of the kit. Screw the column bases to the base top with 10mm m3 nuts and bolts as show. Make sure the columns fit into the slots shown.

Screw the column bases to the base top with 10mm m3 nuts and bolts as show. Make sure the columns fit into the slots shown. Take the Solenoid Mount plate and upright frame

Take the Solenoid Mount plate and upright frame and place them into the slots shown

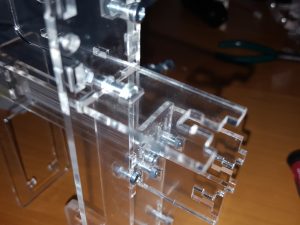

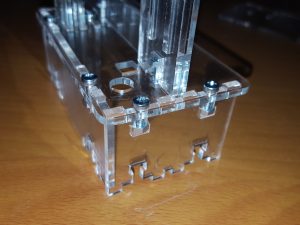

and place them into the slots shown Bolt into place with 2 x 10mm m3 bolts, add the centre plate and bolt into position with a single m3 x 10 mm bolt.

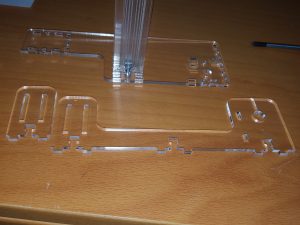

Bolt into place with 2 x 10mm m3 bolts, add the centre plate and bolt into position with a single m3 x 10 mm bolt. Bolt on the front plate with 2 x 10mm m3 bolts

Bolt on the front plate with 2 x 10mm m3 bolts bolt on the left end plate 2 x 10mm m3 bolts

bolt on the left end plate 2 x 10mm m3 bolts bolt on the right end plate 2 x 10mm m3 bolts

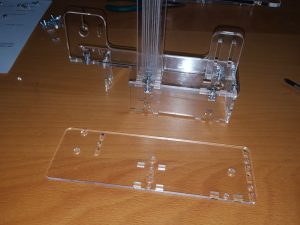

bolt on the right end plate 2 x 10mm m3 bolts take the bottom plate

take the bottom plate and bolt it onto the left,centre,front and right plates with 6 x 10mm m3 bolts

and bolt it onto the left,centre,front and right plates with 6 x 10mm m3 bolts Take the beam and bolt in in the centre

Take the beam and bolt in in the centre with a single 16mm m3 bolt and a nylock nut. Tighten to allow movement

with a single 16mm m3 bolt and a nylock nut. Tighten to allow movement at the flywheel end of the engine attach the 75mm long pull rod to the beam with a single m2 x 10mm and nylock nut

at the flywheel end of the engine attach the 75mm long pull rod to the beam with a single m2 x 10mm and nylock nut take four 15mm linkages two m2 10mm bolts and two nylock nuts

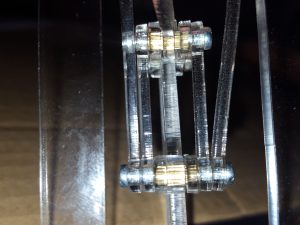

take four 15mm linkages two m2 10mm bolts and two nylock nuts and secure to the beam, tighten to allow movement

and secure to the beam, tighten to allow movement Take the 50mm push rod, and two 25mm linkages, a 6mm m2 threaded standoff and two m2 x 8mm bolts

Take the 50mm push rod, and two 25mm linkages, a 6mm m2 threaded standoff and two m2 x 8mm bolts push the standoff through the two linkages on the beam with the push rod in the centre

push the standoff through the two linkages on the beam with the push rod in the centre screw in the two 25mm linkages at either end of the standoff using the m2 x 6 mm bolts

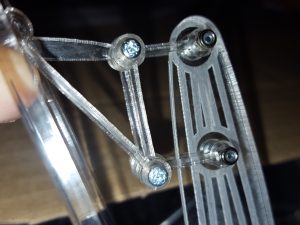

screw in the two 25mm linkages at either end of the standoff using the m2 x 6 mm bolts take the two 35mm open ended linkages, a m2 standoff, a 3mm thick spacer and two m2 x 8 mm bolts

take the two 35mm open ended linkages, a m2 standoff, a 3mm thick spacer and two m2 x 8 mm bolts insert the m2 x 8mm bolts through the open ended linkages

insert the m2 x 8mm bolts through the open ended linkages Clip the linkages on to the turrets on the gallery

Clip the linkages on to the turrets on the gallery Push the m2 bolts through the hanging 25mm linkages

Push the m2 bolts through the hanging 25mm linkages swing the linkages to the m2 stand-off, put the 50mm push rod in the middle (on the stand-off) and screw together

swing the linkages to the m2 stand-off, put the 50mm push rod in the middle (on the stand-off) and screw together View from underneath of the completed linkage

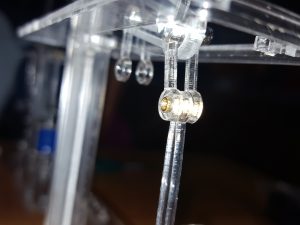

View from underneath of the completed linkage Press one of the bearings into the rear bearing block

Press one of the bearings into the rear bearing block press the other into the upright frame

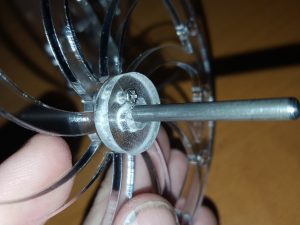

press the other into the upright frame Take the 20mm m2 bolt the flywheel, axel and the hub

Take the 20mm m2 bolt the flywheel, axel and the hub Push the axel through the flywheel and put the m2 bolt through the hub

Push the axel through the flywheel and put the m2 bolt through the hub Push the hub on to the axel and through the flywheel, secure tightly with an m2 nut.

Push the hub on to the axel and through the flywheel, secure tightly with an m2 nut. place a star spacer on the head side of the hub

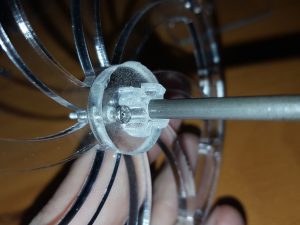

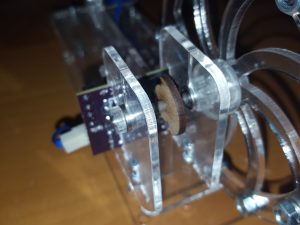

place a star spacer on the head side of the hub Slide the axel through the upright frame and slide the cam to the middle of the axel.

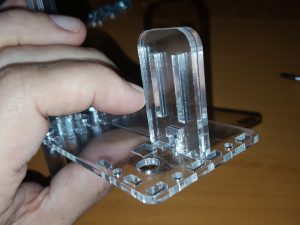

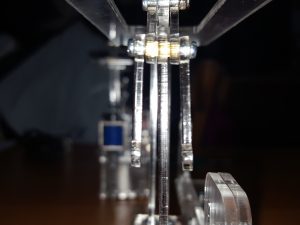

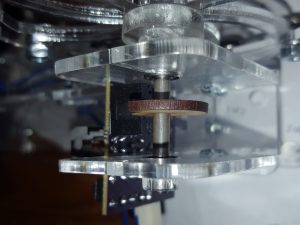

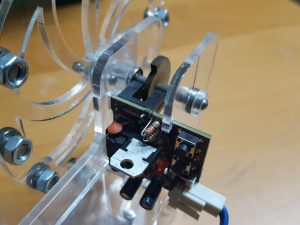

Slide the axel through the upright frame and slide the cam to the middle of the axel. Fit the PCB into place using the registration holes/tabs in the acrylic

Fit the PCB into place using the registration holes/tabs in the acrylic Bolt in the rear axel support to the base with a 10mm m3 nut and bolt.

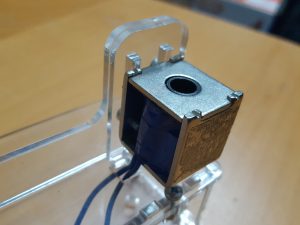

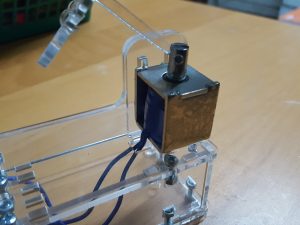

Bolt in the rear axel support to the base with a 10mm m3 nut and bolt. Screw in the Solenoid using the 2 x m3 6mm bolts into the slots

Screw in the Solenoid using the 2 x m3 6mm bolts into the slots Bolt the 50mm push rod to the solenoid with an m2 x16mm bolt and a nylock nut

Bolt the 50mm push rod to the solenoid with an m2 x16mm bolt and a nylock nutApologies, for some reason the Instructions below this point have become corrupt. I’m currently working on replacing them

This diagram should give you the rest of the detail you need.

As the Acrylic some times had a very slight bend in the centre column you may need to add a 2mm spacer before the 3mm star to prevent the flywheel weights from fouling the conrod.

If you have any problems, please get intouch.