Take the base and apply the 10mm strip of aluminium foil over the top of the two 3mm holes at either end.

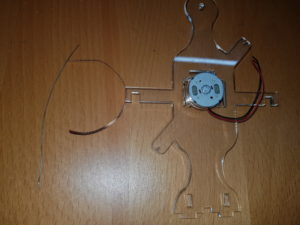

Take the base and apply the 10mm strip of aluminium foil over the top of the two 3mm holes at either end.Take one of the supports and screw in the motor with 3 1.7mm x 5mm screws

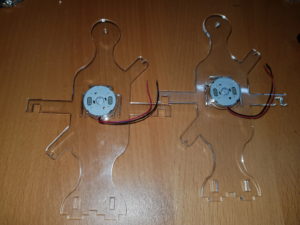

Screw in the other motor in the same way, but ensure that the two are attached in the same way around

Screw in the other motor in the same way, but ensure that the two are attached in the same way around Bend the piece of wire into a slight curve so it will fit from slot to slot in the neutraliser bars.

Bend the piece of wire into a slight curve so it will fit from slot to slot in the neutraliser bars. Cut lengths of braid to 15mm long and slot into the slots in the neutraliser bars

Cut lengths of braid to 15mm long and slot into the slots in the neutraliser bars So they point away from the motor,

So they point away from the motor, Secure them and the curved wire with a small piece of foil. Repeat for the other braid and slot, connecting the two braids with the wire.

Secure them and the curved wire with a small piece of foil. Repeat for the other braid and slot, connecting the two braids with the wire. Place the disk onto the motor spindle.

Place the disk onto the motor spindle. Ensure the braids are lightly touching the foil disks and the discs can rotate freely.

Ensure the braids are lightly touching the foil disks and the discs can rotate freely.Build up the other side and neutraliser bars in the same way

Using the 20mm m3 standoff attach the two halves together

Using the 20mm m3 standoff attach the two halves together Place the bottom of the two halves into the base.

Place the bottom of the two halves into the base. Screw in the capacitor assembly to the base with 10mm x m3 bolts and screws.

Screw in the capacitor assembly to the base with 10mm x m3 bolts and screws. Hook the bars into the slots on the capacitor assemblies.

Hook the bars into the slots on the capacitor assemblies.Add the four feet to the base.