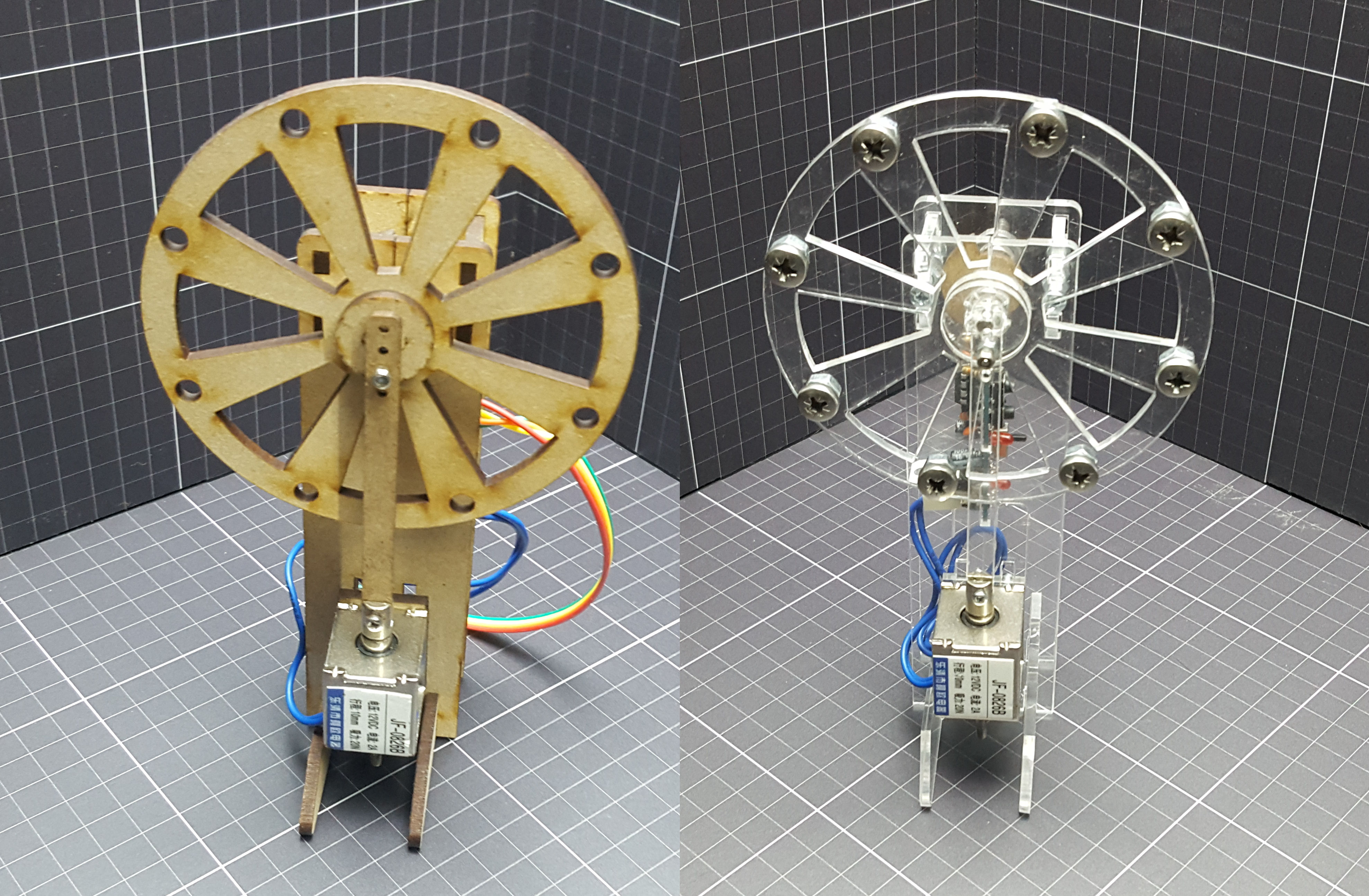

After over a year of selling single solenoid engines we have learnt a lot. Some things from our own development and some from customer comments, so it was time for a complete rebuild of the Solenoid Engine Single.

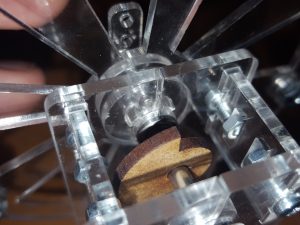

One thing we definitely didn’t like was the foil on the flywheel, It didn’t look too good, and could be difficult to get the opto sensor to trigger reliably, it always seamed a faff to set up. So its gone. It has been replaced with a can and slotted opto, this method is much more reliable and easier to set up. As the axle now needs to move rather than be fixed, it also gave me the opportunity to bring out the engines output to the back of the motor so it can be used to drive some other kits (watch this space) .

It has been replaced with a can and slotted opto, this method is much more reliable and easier to set up. As the axle now needs to move rather than be fixed, it also gave me the opportunity to bring out the engines output to the back of the motor so it can be used to drive some other kits (watch this space) .  The mount for the solenoid has changed this gives two advantages. The screws for the solenoids are now easily accessible to move the solenoid for setup and the con-rod now connects to the centre of the solenoid armature meaning that the motor will run more smoothly.

The mount for the solenoid has changed this gives two advantages. The screws for the solenoids are now easily accessible to move the solenoid for setup and the con-rod now connects to the centre of the solenoid armature meaning that the motor will run more smoothly.

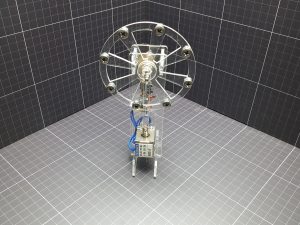

The final change is that the engine is now available in MDF as well as the original Acrylic.